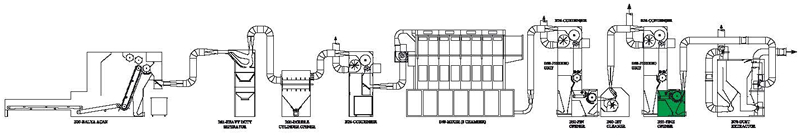

The cylinder of the BALKAN FINE OPENER is wrapped with a saw-tooth wire. The flow of the cotton is achieved with a frequency controlled reduction motor. The cotton is fed to the cleaner through double cylinders covered with identical saw-tooth wire to avoid fiber damage.

This ensures that the fibers are not torn off ,but combed. The fibers that go through two blades below the opening vane are directed by the combing segment. Air moves through at a greater speed than the vanes, and pulls the fibers out. The Fine Opener prepares the cotton for optimal carding, ideally opened, and separated into the smallest fiber clusters.