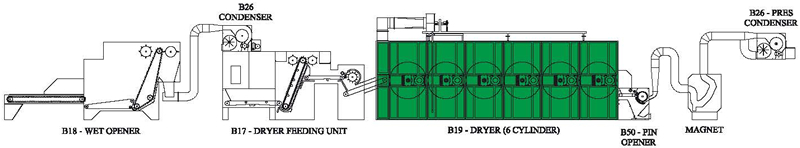

Material that comes from the feeding unit to the B19 DRYER adhere to the vacuum surface and starts rotating with sieve. Sieves is closed crossing and rotation process begins in the first sieve, then continues until the last sieve and output hood.

While the material flows in the machine, from input to output, the fans that mounted the sieves suction trough the sieves and provides the adhesion to the material at the sieves. At the same time fans suck air that through the sieve, blows out the air strongly. And the hot air in the serpentines blows on the material with the help of air baffle in the machine.

In these process, moisture in the machine throws away with exhaust fan.B19 DRYER is composed of six sections and each section has its own fan. The degree of drying is completed in three stage. Sections that combined as double and thermocouples in that sections provides drying of material and also controls of it.